CO2 emissions from transport

Improvements in vehicle scheduling

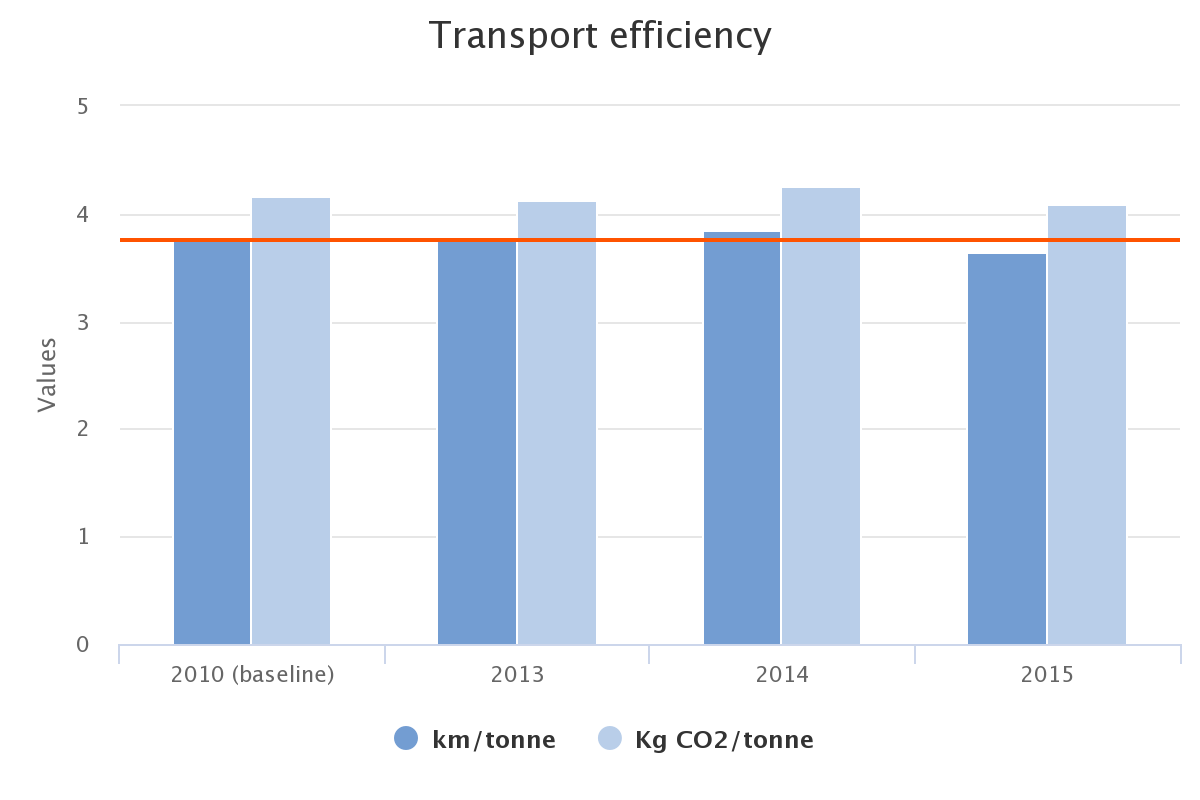

CO2 emissions from transport on a per tonne basis fell slightly during the year as a result of better vehicle scheduling. We also had a higher percentage of our own vehicles meaning we could track fuel use more accurately and provide fuel efficiency training for all our drivers. Rail deliveries increased slightly for aggregates but cement was static.

A project to optimise order handling and vehicle scheduling in the aggregates, asphalt and concrete business lines is ongoing. The aim is to improve vehicle use and reduce fuel costs. The project is focused on the effective and efficient use of our delivery fleet through the introduction of vehicle optimisation software, GPS and a material resource planner (MRP) to schedule internal deliveries.

-

CO2 emissions from transport

Transport efficiency

2010 (baseline)

2013

2014

2015

Tonnes delivered

29,529,302

26,354,963

27,212,523

28,473,246

kg CO2 / tonne

4.16

4.13

4.25

4.09

Total distance travelled km

111,677,281

98,793,441

104,436,393

103,660,621

Tonnes CO2 / year

122,934

108,824

115,602

116,397

-

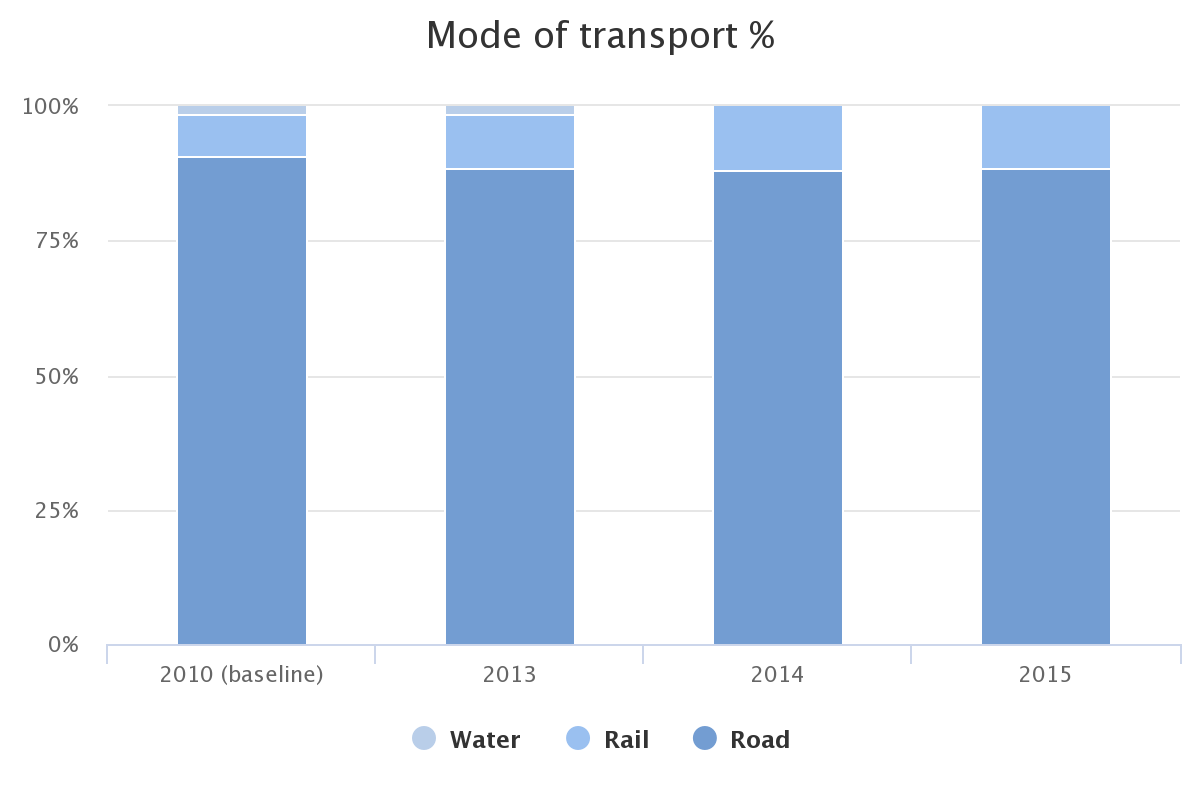

Mode of transport

Mode of transport

2010 (baseline)

2013

2014

2015

Road

90.78

88.65

87.75

86.55 Rail

7.91

10.02

11.76

11.45 Water

1.31

1.33

0.5

2.0

Rail wagons on track

A fleet of 19 new cement rail tankers went into service during the year. The VTG Rail wagons were built by Feldbinder in Wittenberg, Germany, and are being used for cement deliveries from the Ribblesdale works in Clitheroe to Bellshill depot in Glasgow, and Avonmouth depot near Bristol. We also move cement by rail from Ketton to a depot at Kings Cross in central London.

The net effect was to increase train carrying cement capacity from 1,050 tonnes to 1,400 tonnes on all three rail routes.

Moving floor trucks eliminate tipping

The latest addition to the Hanson transport fleet is an articulated trailer that doesn’t tip. The load is discharged by a series of sweeping rams which push the material out of the truck. All the traditional risks for associated with tipping articulated trucks - high winds, uneven ground or overhead trees and cables – are eliminated. And the trailers are perfect for sites in tunnels or underpasses. Read more