Water

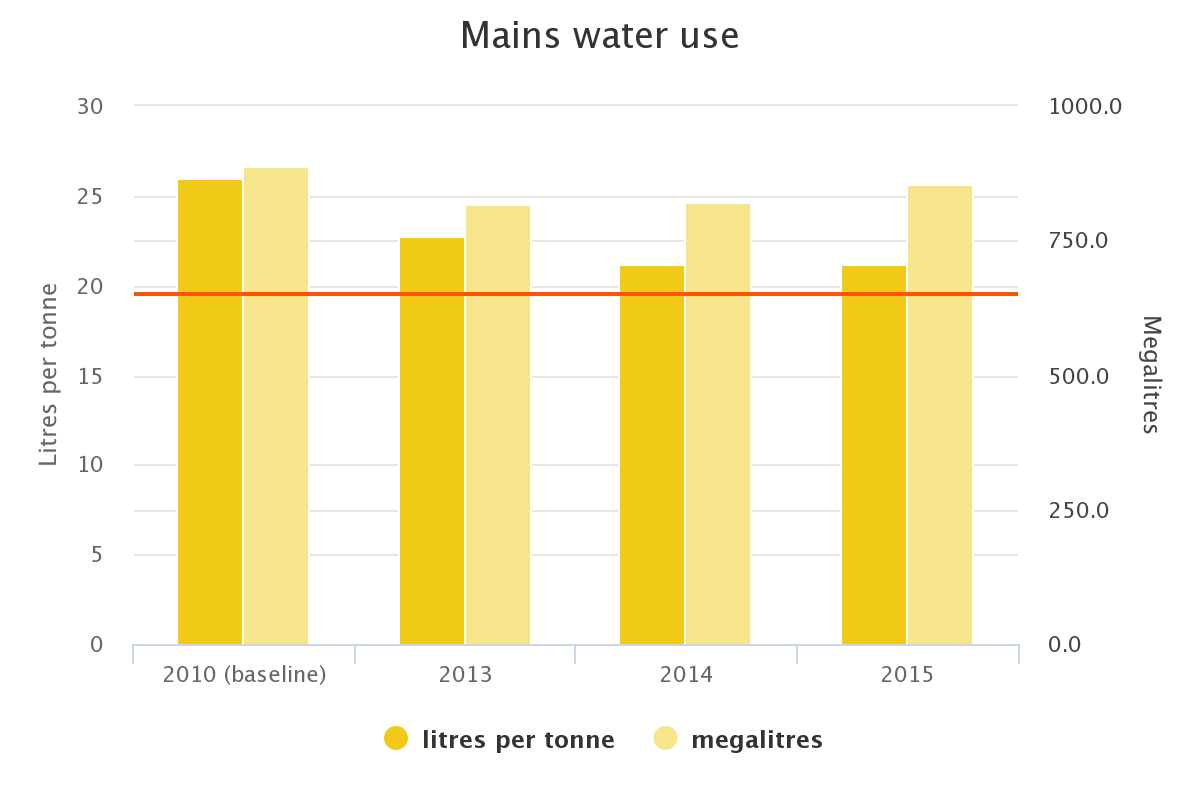

Water use per tonne falls by 20 per cent

We use water as an essential raw material in many of our products, particularly concrete. It is also used to wash sand and gravel, to suppress dust, and to operate lorry wheel washes.

Our mains water bills are monitored by Waterscan, who run checks on actual consumption in relation to expected, allowing us to reduce consumption and identify leaks. Site managers also record monthly water consumption on our database, Entropy. Wherever possible, we harvest and recycle water or pump ground water from boreholes, lakes or rivers for our manufacturing processes ahead of using mains water.

Overall water use per tonne of product fell by 20 per cent. The majority of this was ground water in the aggregates business line, but there was also a slight fall in mains water use and we continue to raise awareness of the need to conserve mains water. Our target to reduce total water per tonne of concrete is proving challenging.

-

Water consumption data

Water consumption

2010 (baseline)

2013

2014

2015

Mains water consumption – megalitres

26.03 22.75 21.24 21.23 Mains water consumption – megalitres

890.0 819.1 823.0 853.2 Total water consumption – megalitres

8,861.9 8,473.7 8,881.4 7,320.3 Total water consumption – litres per tonne

285.20 235.34 229.18 182.15 Concrete total water consumption – litres per tonne

85.99 77.57 87.66 88.84 Click here for data by business line

Target: Reduce mains water consumption by 25 per cent by 2020 based on 2010 baseline; reduce the sum of mains and abstracted water for concrete by 10 per cent by 2020 based on 2010 baseline.

Waste water is captured and reused

The Glasgow central ready-mixed concrete plant at Jessie Street, Polmadie, features a highly efficient water harvesting system which means that mains water is rarely – if ever – used in the production process. Read more